Meat use-by dates – an exercise in both risk and crisis management

The following article was written by Nick Allen, CEO of BMPA and appeared in the April edition of New Food magazine as part of an in-depth country profile on the United Kingdom. It is reproduced here with their permission.

Recent high profile product recalls and withdrawals have shaken the confidence of retail buyers and consumers alike. To complicate matters, there has been considerable confusion when trying to distinguish between failures to follow guidance (which can be remedied) and serious, fraudulent or criminal activity.

The larger retail and hospitality chains have in-house technical teams they can call on to navigate their way through the complicated, and in some cases overly precautionary, official food safety guidance. They can separate fraud from less serious enforcement issues and work constructively with their suppliers to ensure they are applying the right rules to different meat products.

However, smaller groups, intermediate food manufacturers and individual buyers often lack that detailed information and have been imposing a blanket restriction on product use-by dates without understanding the full facts. This has led to needless food waste and disruption to the supply of products that would actually comply with the FSA’s guidance.

Responsibility falls on meat processors and manufacturers to not just ensure they are compliant with FSA guidance but to communicate clearly and openly with their customers to demonstrate that compliance.

Managing the risks

Whether a Food Business Operator (FBO) is compliant or not revolves around being able to demonstrate to an FSA auditor that the company’s food safety management procedures are based on Hazard Analysis and Critical Control Point (HACCP) principles; that a plan is in place; and that it is being applied correctly.

FBOs must demonstrate that the risks have been considered and understood and also provide evidence of relevant control procedures. This can be done by gathering internal documents, FSA 2017 guidance and other existing scientific data as evidence to support your manufacturing process decisions.

A number of methods can be used to gather this evidence, which range from predictive microbiology modeling through to historical data and specific laboratory shelf life studies.

Know your entire supply chain

botulinum will not grow below three degrees. As part of a company’s HACCP plan, consideration must be given not just the temperature during manufacture and packaging, but also the likely temperature a product will be held at throughout the entire supply chain. This includes distribution, retail and the end customer.

Manufacturers will need to satisfy an auditor that the risk of C. botulinum growing has been considered during the whole shelf life of the product.

In addition to considering what happens to meat products when they leave the factory, manufacturers must also take into account what happened before they arrived. This means understanding how those products have been processed and stored at every step of the way.

A spokesman for the FSA confirmed that “A food business in another EU country or a third country supplying businesses in the UK should ensure the food products they supply is safe, should have control factors in place to justify the shelf lives they apply and should ensure that the product will remain safe during the shelf life they apply.

“UK food businesses ordering vacuum packed or modified atmosphere packed cured meat products from another country should ensure their supplier has appropriate controls in place.”

Firms must satisfy themselves that they’ve looked at the technical details, understood what they need to do and then implemented the right measures.

Official guidance and the 10-day rule

The ’10-day rule’ can be confusing and the date it is applied from will depend on how products have been processed and stored.

The FSA has published full guidanceas well as a shorter fact sheet that provide details on what manufacturers should have in place to remain compliant. The BMPA has also issued information about the elements that should be considered when assessing adequacy of risk mitigation for C. botulinum in chilled vacuum / MAP foods.

The following check list is intended as an overview.

- Below temperatures of 3C, C. botulinum, will not grow

- A maximum 10 day shelf life (use-by date) is recommended for VP/MAP foods stored at temperatures between 3-8C if other controlling factors are not used

- For a shelf life of more than 10 days, in addition to chill temperatures, controlling factors should be used either on their own or in combination

Controlling Factors

- Heat treatment of 90 degrees centigrade for 10 minutes, or a time and temperature combination sufficient to kill C. botulinum spores. This must be reached in the part that takes the longest time to heat up, e.g. in the centre of the food and have been applied to the product in the sealed finalpack

- PH of 5 or less in all parts of the food. Foods containing meat or fats are very difficult to acidify uniformly and extra care should be taken

- Minimum salt level of 3.5% in the water phase throughout all parts of the food

- Water activity of 0.97 or less in all components of the food

- Combination of the controlling factors can be used at lower levels or with other preservative factors, such as nitrite. But, these must be shown to be safe using expert scientific advice.

Further processing and re-wrapping

Rewrapping VP/MAP foods: If a VP/MAP product is unwrapped for slicing or portioning and then rewrapped as a VP/MAP product, the shelf-life should not be extended beyond the shelf-life of the original VP/MAP product.

When VP/MAP foods are used as ingredients in other products, the shelf-life should not be extended beyond the shelf-life of the original ingredients, unless it has received a treatment that is sufficient to kill or stop the growth of harmful bacteria.

Frozen food

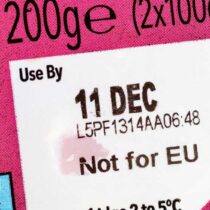

In the case of meat that has to be frozen and then sold on after the original use-by date has expired, companies must be able to demonstrate when freezing was undertaken and provide instructions on how the product can be further used.

If the freezing date is not documented there will be no proof that this was undertaken prior to the use-by date expiring and the product cannot be sold on.

Managing expectations

To put the risks into perspective, over the last 30 years the UK’s chilled food industry has produced an estimated 20 billion chilled ready meals and a similar number of other vacuum packed raw and cooked products. In that time there have been no reported cases of C. botulinum food poisoning from meat with shelf lives up to 10 days and more. Issues have only ever arisen when foods have not been stored at the correct temperature either during sale or in the home, which is not a production issue. This clean track record has been demonstrated by an extensive review commissioned by the FSA.

One of the major findings of a series of recent publicly funded, peer-reviewed studies (producing the largest data set of it’s kind in the world) is that fresh meat actually had the lowest spore loading of anyfood category. This adds to a growing body of evidence that suggests vacuum and modified atmosphere packed meat (VP/MAP) is a much lower risk than previously thought.

How can manufacturers re-assure meat buyers?

The British Meat Processors Association advises suppliers to provide clear information about the products they sell in the form of a technical specification for each product. This should include information proving that the product has been processed and stored according to FSA guidelines to justify the use-by date quoted.

Buyers may also want to check a supplier’s latest FSA audit results on the ‘Approved Establishments’ register. If you have had any breaches you should be prepared to discuss this with your customer to clarify what kind of breach it was and what has been put in place to remedy it.

With all the negative publicity surrounding certain high profile manufacturers, it’s sometimes difficult for buyers to understand what is a serious (often criminal) breach and what would be considered less serious and, above all, rectifiable.

Open, clear and honest communication backed up by documented evidence is key to this kind of expectation and crisis management.

An evolving situation

This is a complicated and changing issue and the latest guidance has imposed extremely precautionary restrictions on the shelf life of meat and meat products.

Working closely with the FSA, the British Meat Processors Association is currently conducting four research programmes that will help regulators to better understand the risk of botulism from chilled VP/MAP fresh meat and assist in setting more technically appropriate restrictions that, in turn, will provide confidence to producers, buyers and consumers.

BMPA has comprehensive and detailed information for its members as well as a helpline to assist member companies to understand and apply the FSA’s guidance. As findings become available from ongoing research projects, the results and further advice will be made available to both members and non-members that wish to participate in these projects.