Recent product recalls leave meat industry looking for answers

The British Meat Processors Association has been working closely with the Food Standards Agency (FSA) to understand what has prompted some of the recent high-profile product recalls and withdrawals. At the centre of the problem are a number of related issues that surround how food businesses are dealing with the control of the Clostridium botulinum bacterium.

Non-proteolytic Clostridium botulinum is a bacterium that survives in the absence of oxygen, for example in vacuum packs. It produces a very powerful toxin in food, which causes serious illness and can be fatal.

The FSA has instigated product recalls and withdrawals for businesses that they have found are not complying with their recently updated guidance issued in June 2017 on the control of this bacterium. This guidance forms part of their broader Hazard Analysis and Critical Control Point (HACCP) procedures, which all food businesses are required to implement. One of the things they check when conducting their routine site inspections is that businesses have an appropriate HACCP-based food safety management system in place.

The FSA has identified that, in some meat plants, HACCP plans are not sufficient to ensure the safety of their products and that they have neither considered nor understood the risks associated with Clostridium botulinum.

BMPA Technical Policy Advisor, David Lindars said “We are taking this matter very seriously and have already provided initial guidance to our members. However, we will continue to work with the FSA and will be keeping members updated with more detailed information over the coming weeks. We currently have four projects running with regard to Clostridium botulinum.

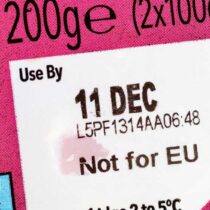

Use by dates

Use by dates are often cited as being the reason behind product recalls and withdrawals. In the absence of any other control, for example, a low pH, high salt content, low water activity, temperature less than 3 degrees C throughout the chain, the most commonly recommended means of controlling Clostridium botulinum is to limit the chilled shelf life to 10 days if there are no controlling factors.

However, it has emerged that many businesses have extended shelf life beyond 10 days without applying effective controls as set out in the HACCP guidance.

Best before dates

Another related issue is that the industry currently uses many different forms of durability date formats, for example ‘process by or use between to use by’. The concern here is that raw material can take many different routes through the processing chain to the final pack and is often sold-on for further processing before reaching the final consumer.

In the eyes of the FSA, ‘use by date’ means the end of life. In other words, that raw material cannot then be used in a product with another 10 days life. This means that businesses need to ensure they have risk assessed the whole of the chain from raw material to the final pack.

Mr Lindars said “If a company is currently showing ‘use by’ on any raw material, the advice from BMPA is to consider changing the wording to ‘process by’ or something similar to make it clear when the end of life should be regardless of whether it goes on for further processing.”

FSA Guidance

The FSA have produced detailed guidance on this issue, which you can download here along with a shorter overview factsheet.

In a statement they said; ‘this guidance is recommended for use by manufacturers and retailers of chilled vacuum and modified atmosphere packed (VP/MAP) foods and focuses on the control of non-proteolytic Clostridium botulinum in vacuum packed products, including an explanation of the “10-day shelf life rule”.